Side discharge bin unload systems can save time and energy when used correctly. They use gravity to partially unload grain from a bin. But proper operation and placement of these systems is crucial to protect bins from damage.

Category: Storage

The Dos and Don’ts of Grain Bin Unloading – Part 1

A bushel of corn at 15% moisture weighs about 56 pounds. With capacities of Brock grain bins reaching nearly 2 million bushels, that weight creates tremendous pressure on the bin sidewalls. In this article, Shawn Gearhart, District Manager for Brock Grain Systems, explains why proper unloading practices using center and intermediate floor sumps are essential for maintaining bin integrity.

Pre-Season Grain System Prep Pays Off

Before harvest season kicks into full gear, it’s essential to ensure your grain storage, handling, and drying equipment are ready. In this article, product experts from Brock Grain Systems share key tips to help you prepare for a smooth, efficient harvest and a worry-free storage season.

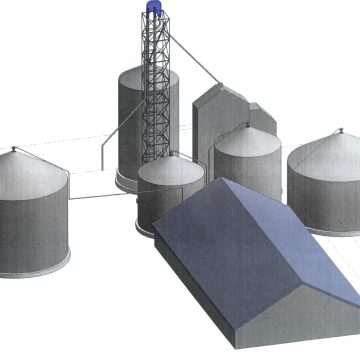

On-Farm Grain Storage is All About Control

When it comes to safeguarding your grain, there’s nothing wrong with being a control freak. An on-farm grain storage system can put you in the driver’s seat when it comes to avoiding bottlenecks at harvest, protecting your grain’s value, and getting the most out of market timing. Iowa State University grain quality specialist Charles Hurburgh talks about some of the considerations for storing, handling and drying grain.

Keeping Up With Harvest at Ivers Farms

Every year, Ivers Farms harvests corn and soybeans from approximately 11,000 acres in southeast Illinois and southwest Indiana. They store most of that grain on the farm. So it’s important they have the storage capacity and speed to keep their combines and trucks running.

4 Ways On-Farm Grain Storage Can Improve Profitability

On-farm grain storage systems have many benefits for farmers. From saving money on storage costs and drying to having easier, around-the-clock access to grain, on-farm storage allows farmers more flexibility and control when it comes to selling after harvest.

Generations and Storage Bins Come in Multiples at Larson Farms

Chet Larson represents the fifth generation at Larson Farms, which has been in operation since 1918. Like many farms, the Larson’s grain storage bin system has grown with the expansion of their farming operation. They have several Brock grain bins and multiple pieces of Brock handling equipment, including two GrainDrive™ T1000 Tube Conveyors.

One-of-a-Kind Grain System in Swayzee, Indiana

On the welcome sign outside of town, Swayzee claims to be “the only Swayzee in the world.” Carey Farms, located nearby, can make a similar claim about their unique grain operation. Learn more about what makes their Brock grain system stand out and how it’s built for future growth and expansion.

How Not to Handcuff Yourself when Planning On-Farm Grain Storage

There are many reasons farm operations might want to expand grain storage and drying systems — harvest schedules, marketing flexibility, drying costs. Whatever your reasons, make sure you plan ahead to give yourself future options and flexibility. We asked Bill Winchell, District Manager at Brock Grain Systems about the things to consider when planning for expansion.

4 Sure Signs It’s Time For a Tube Conveyor

Your grain storage and handling system may be telling you that it’s time to consider a new way to move grain. The question is, should I upgrade now to a tube conveyor? The answer is often, “yes,” according to Tyler Ginder, Product Manager of Handling Systems for Brock Grain Systems.