A bushel of corn at 15% moisture weighs about 56 pounds. With capacities of Brock grain bins reaching nearly 2 million bushels, that weight creates tremendous pressure on the bin sidewalls. In this article, Shawn Gearhart, District Manager for Brock Grain Systems, explains why proper unloading practices using center and intermediate floor sumps are essential for maintaining bin integrity.

In Part 2 of the series, Shawn will cover the correct placement and operation of side discharge unload systems.

Shawn Gearhart, District Manager at Brock Grain Systems

Pitfalls of grain bin unloading.

“While grain bins are specifically engineered to hold the forces of large amounts of grain, it’s very important for operators to be aware of the pitfalls of grain bin unloading,” said Gearhart. You might have an employee inadvertently open an intermediate sump, or a truck driver from a grain cooperative open the wrong lever. The examples in this article show how damage can occur with just a few hundred bushels of grain being emptied.

Do

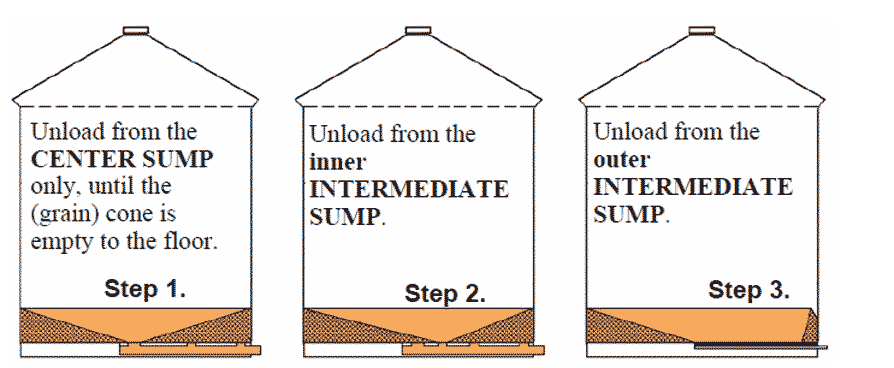

- Unload from the center sump only until the bottom of the grain cone reaches the floor.

- Open intermediate sumps one at a time moving from the inner to the outer bin.

- Consider adding locks to intermediate sump controls to prevent accidental off-center unloading.

- If your unload system fails, contact a qualified dealer for guidance and recommendations.

Don’t

- Open any of the intermediate sumps until the grain cone reaches the floor through the center sump.

- Never unload from the outer sumps until all grain has been unloaded from the center sump and any intermediate sumps closer to the center.

- Use intermediate sumps for blending grain.

Even a small margin of error can cause a bin to fail.

Even though the intermediate sumps appeared to be closed from the outside of the bin, these small gaps in the intermediate wells caused the sidewall failure in the bin shown above.

Protect the safety of people first.

When a bin begins leaning, and especially if grain is actively spilling from open seams in the sidewalls, be sure to evacuate everyone from the area. Don’t be tempted to stand close to get a good picture.

Proper grain bin unloading.

“To maintain equal pressure on all sides of the bins, you must unload all of the grain from the center of the bin before opening any intermediate sumps,” explained Gearhart. “This way, the grain falls away from the wall to form an inverted cone with the pressure remaining equal all the way around the bin.”

Continue monitoring grain flow for consistency, watch for unusual noises or vibration, and check for signs of spoilage or crusting. Once unloading is complete, clean out remaining grain and inspect the floor, sumps, and unload system for buildup or damage before closing the bin.

Importance of installing an emergency sump.

When the center sump in this bin became blocked, the operator attempted to unload through the side door using an improper method.

Emergency sump.

“Because it’s such an important feature, an emergency or alternate sump comes standard with all Brock grain bin unloading equipment,” said Gearhart. An emergency sump is controlled independently from other intermediate sumps and is only used if the center sump is plugged by grain or becomes mechanically inoperable. It must be in the center quarter of the bin (e.g., within 6 feet of the center for a 48-foot bin). Incorrect use without an emergency sump risks off-center unloading and damage to the bin.

Watch this demonstration highlighting the importance of proper bin unloading.

Other Resources

More information about unloading grain bins is available in the Brock Grain Systems operator’s manual. »

To get more helpful tips like this, subscribe to Brock News »

Request more information about BROCK Grain Systems.