Photo courtesy of Agri-Systems, Inc.

Side discharge bin unload systems can save time and energy when used correctly. They use gravity to partially unload grain from a bin. But proper operation and placement of these systems is crucial to protect bins from damage. In Part 1 of this series, Shawn Gearhart, District Manager for Brock Grain Systems, explains why proper bin unloading practices using center and intermediate floor sumps are also important.

Shawn Gearhart, District Manager at Brock Grain Systems

BROCK® Side Discharge Bin Unload Systems.

“Sometimes called side draws, these systems allow unloading of free-flowing grain from corrugated, stiffened grain bins by gravity alone,” said Gearhart. “They can save operators a lot of electricity over the life of the system and are very reliable. But to protect grain bins, we always stress the importance of installing and using these systems properly.”

Do

- Position side draws at or above the second ring/tier of the bin.

- Provide adequate quantity of clean roof vents when side discharge systems are used to prevent a vacuum inside the bin that could collapse the roof.

- After unloading through a side discharge and before refilling the bin, unload through the center sump to achieve an inverted cone with level grain depth around the perimeter of the bin.

- If your unload system fails, contact a qualified dealer for guidance and recommendations.

Don’t

- DO NOT INSTALL a side draw in a non-stiffened bin, unless stiffeners are installed below the spout on both sides of the side draw system.

- DO NOT USE a side discharge if air gates have been installed. Electric gates may be used if they close at a SLOW, controlled speed equivalent to a hand-operated gate.

- DO NOT UNLOAD from the side discharge system and the center bottom discharge at the same time.

- DO NOT UNLOAD from two side discharge systems at the same time. A second side discharge may be installed in some bin diameters. See the installation manual for details.

- DO NOT ALTERNATE unloads if multiple side discharge systems are installed in the same bin.

- DO NOT USE a side discharge and fill the bin at the same time.

Proper placement and installation.

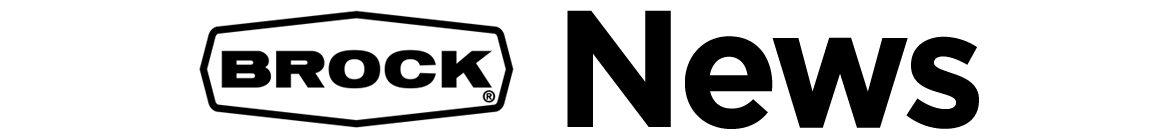

The spout for a side discharge can be installed as low as the second ring/tier, but not below the second ring/tier. The spout cannot be installed on a vertical or horizontal seam. Some bins may require additional wind rings. “Bins with side draws must have manufacturer-designed interior baffles installed from the top of the bin to the side discharge spout,” said Gearhart. “These baffles ensure only grain from the top of the bin is safely unloaded.” Side discharges which are improperly installed or made by other manufacturers could result in sidewall damage and could void the BROCK® Bin Warranty.

Side discharge systems operated without baffles installed create uneven pressures that can cause roof damage, sidewall flattening or buckling.

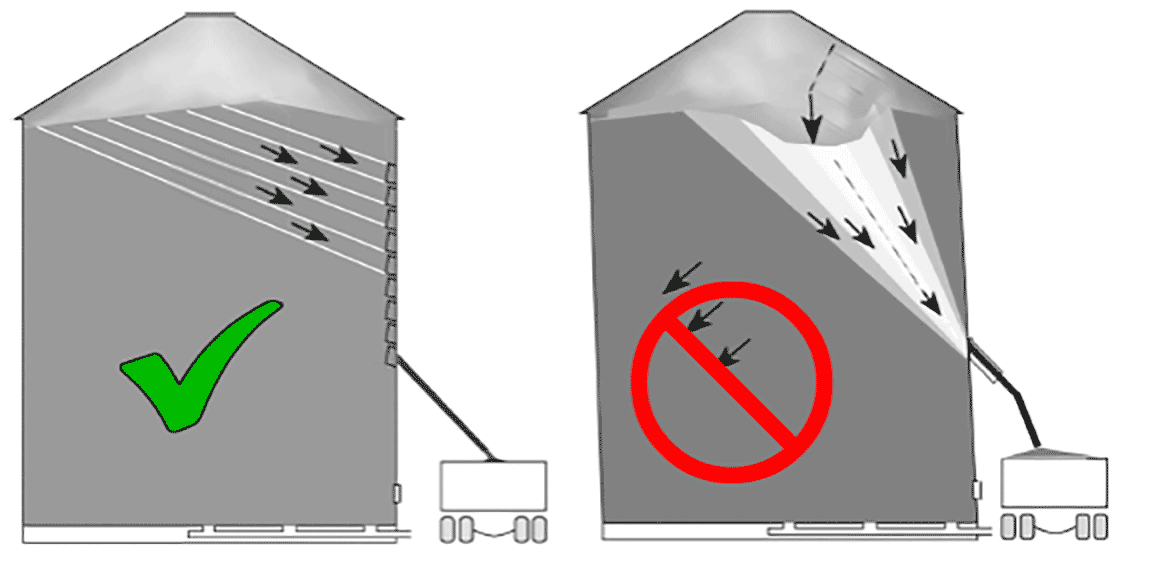

Proper refilling.

“Even with a proper side discharge system, you must still unload through the center bottom sump so grain reaches equal wall heights around the entire bin before you refill,” explained Gearhart. Failure to do so before re-filling will create unequal wall stresses, cause the bin to go out-of-round, and will flatten the side where grain depth is lowest. Bin damage can eventually occur.

Refilling a bin without first leveling the existing old grain can create uneven sidewall pressures and possible bin failure.

Emergency sump.

In part 1 of this series, Gearhart explains the importance of having an emergency or alternate sump in case the center sump is plugged by grain or becomes mechanically inoperable. Having a side discharge system does not replace the need for an emergency sump. The emergency sump must be in the center quarter of the bin (e.g., within 6 feet of the center for a 48-foot bin. Incorrect use risks off-center unloading and damage to the bin.

Watch this demonstration highlighting the importance of proper side discharge unloading.

More information about side discharge unloading is available in the Brock Grain Systems operator’s manual. »

To get more helpful tips like this, subscribe to Brock News »

Request more information about BROCK Grain Systems.