Cross Flow and Mixed Flow are terms that grain dryer manufacturers use to describe different ways that air flows through grain. But which is right for you? Grant Knobloch, Product Manager for Conditioning Systems at Brock Grain Systems, explains the key differences between grain dryers and some reasons you might choose one type over the other.

Airflow basics.

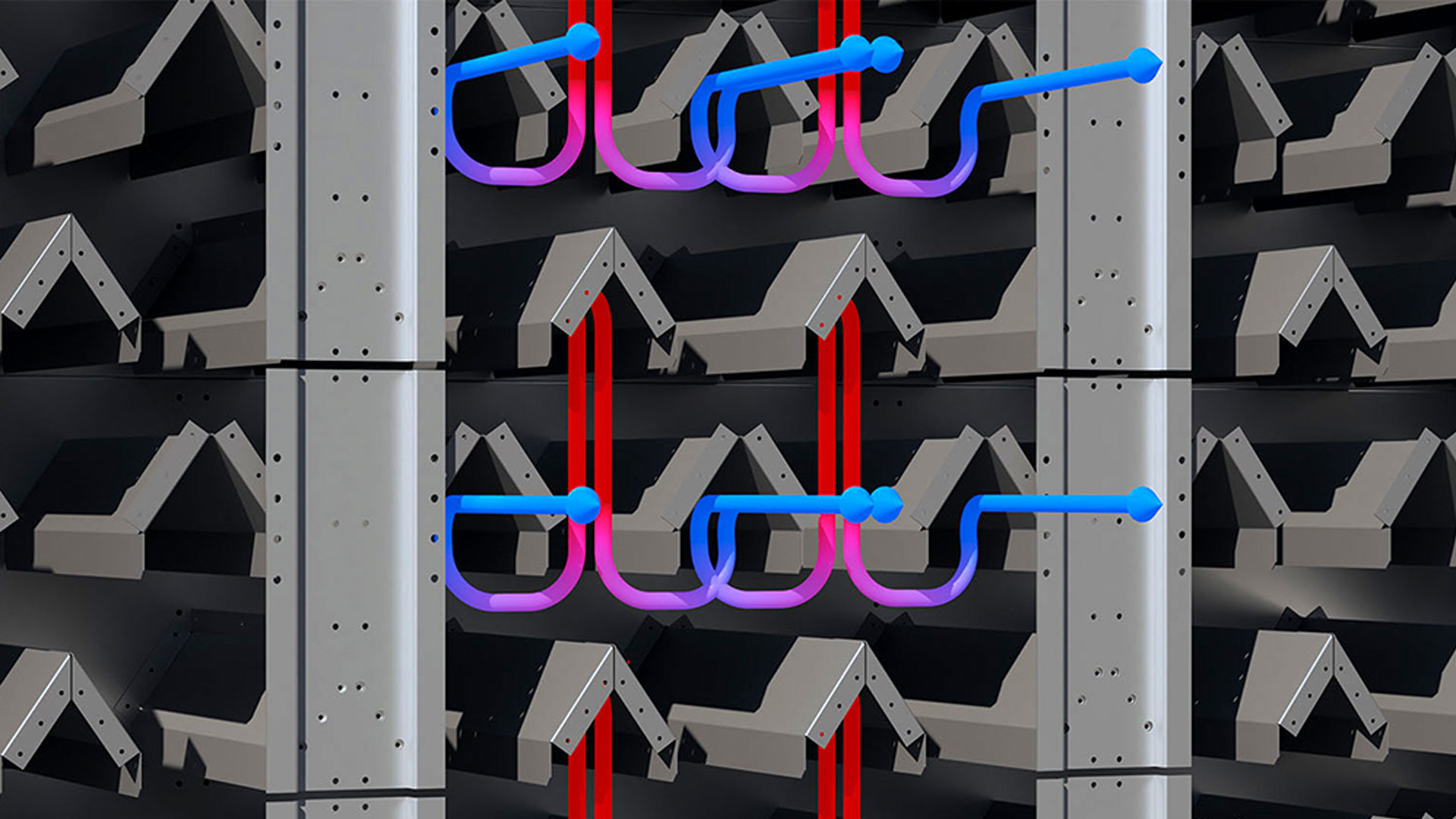

Cross Flow

In most grain dryers, grain moves down a column between inside and outside screens. The air flows horizontally across the moving grain column. This cross flow technique is used in many low-profile dryers and tower dryers.

Mixed Flow

Mixed flow dryers have inlet air ducts which are open to the plenum and closed to the exterior. Air travels upward through the grain and exits through ducts that are closed to the plenum and open to the exterior. This drying system is unique because there are no screens to keep clean.

Capacity first and foremost.

Drying capacity is the first thing to consider when choosing a grain dryer. “You don’t want to pay a premium for more capacity than you need, but you also don’t want an undersized drying system creating a bottleneck during harvest,” says Knobloch. “That’s why Brock provides four different types of dryers to meet customer needs — with capacities ranging from 375 to 10,000 bushels per hour at five points of moisture removal.”

Capacity alone can determine that you need a commercial tower dryer. But sometimes capacity requirements overlap among several dryers. For example, if you need to dry 1,800 bushels per hour, you can choose between a Brock low-profile dryer, a mixed flow dryer, or a mid-sized tower dryer.

SUPERB ENERGY MISER® SQ Series Low-Profile Dryer

375 to 1,800 bushels (9.5 to 45.7 metric tons) per hour

VECTOR™ ENERGY MISER® Mixed Flow Dryer

784 to 2,900 bushels (19.9 to 73.7 metric tons) per hour

MEYER ENERGY MISER® Tower Dryer

1,000 to 2,650 bushels (25.4 to 67.3 metric tons) per hour

BROCK® BCT Commercial Tower Dryer

2,500 to 10,000 bushels (63.5 to 250 metric tons) per hour

Full heat or heat/cool.

“Some dryers run with full heat through the entire process,” says Knobloch. “This increases drying capacity, but since the grain is exiting the dryer at 130 to 150 degrees, it also requires extra management outside of the dryer to get the grain to the proper temperature for long-term storage.

“Heat/cool systems allow you to do some cooling in the dryer before unloading. This allows grain to be conveyed to storage bins with less management and, in some cases, unlocks an energy improvement of 10 to 20%.”

Does your site measure up?

Knobloch explains that dryer footprint size, fill heights, and installation costs are other important considerations when choosing a dryer. “Tower dryers provide high capacity drying in a minimal footprint. For example, the MEYER Tower Dryer can handle up to 2,650 bushels per hour running in heat/cool mode with only a 11 ft 8 in. (3.56 m) diameter.” One tradeoff is that the fill heights of a tower dryer require the use of a grain leg. The VECTOR Mixed Flow Dryer can be filled with tube conveyors or a grain leg. The low-profile dryer is low enough to be filled with a transport auger. VECTOR Mixed Flow and low-profile dryers can utilize takeaway equipment of pneumatic systems, conveyors, augers, or a grain leg.

Installation considerations.

“Low-profile dryers are nice because they are short and compact,” says Knobloch. “The dryer shows up on one trailer, so they’re easy to install. Brock sends jacks with the semi-trailer, so you really don’t need any large equipment to get them unloaded. The VECTOR Mixed Flow Dryer ships in modules that can be assembled with a crane. The MEYER Tower Dryer ships fully assembled on a trailer and is set in place using a crane, while the BCT Dryer is assembled on-site.”

Moisture-based dryer control.

Brock’s INTUI-DRY® Dryer Control comes standard on new BROCK® Commercial Tower Dryers, MEYER ENERGY MISER® Tower Dryers, and VECTOR™ ENERGY MISER® Mixed Flow Dryers. It is an option on new SUPERB ENERGY MISER® SQ Series Low-Profile Dryers. INTUI-DRY Control works in concert with the Brock TrueGrain™ Moisture Sensor System to provide accurate and consistent moisture-based dryer control and remote monitoring.

Worth the effort.

It’s important to remember that all the planning, installation, and operation of a grain drying system is worth the effort. “No matter which grain dryer you choose, they are money-making machines,” emphasizes Knobloch. “A lot of guys look at them as a pain, but they really do make a farmer a lot of money.”

Learn more about BROCK Grain Dryers