Product Feature

BROCK® Commercial Tower Dryers

Just because BROCK® Commercial Tower Dryers have “commercial” in their name, doesn’t mean they don’t have a solid place on the farm. Grant Knobloch, Product Manager for Conditioning Systems at Brock Grain Systems, explains some of the key reasons farm operations are upgrading to these high-capacity, high-efficiency dryers.

Bigger farms mean bigger, faster harvests.

“Farms and harvesting equipment are both getting larger,” says Knobloch. “So as the speed of harvest increases, the farmer’s need to get thousands of bushels of grain into a safe storage condition each day also increases.

“When large farms reach the limits of their drying capacity, they have the option to install a second dryer or install a single dryer that can handle more bushels. But think of having two cars. There are eight tires that you need to keep filled with air. You have two engines that need oil changes. It’s the same with grain dryers. Having one, larger dryer in your operation reduces your maintenance and management.”

Increased drying capacity.

One of the most significant advantages of commercial tower dryers is their remarkable throughput capacity. Continuous-flow BROCK® BCT Commercial Tower Grain Dryers offer drying capacities ranging from 2,500 to 10,000 bushels (63.5 to 250 metric tons) per hour. With faster turnaround times and increased harvesting capabilities, farms can scale their operations to meet growing demand.

Harvesting at higher moisture levels.

“As farmers harvest grain at higher moisture levels, they also need more drying capacity,” continued Knobloch. “A combine can harvest 5,000 bushels of corn an hour and it doesn’t really care what the moisture level is, but your grain dryer does care. The dryer’s ability to keep up with your harvest is determined by the moisture levels coming in. A study from Purdue University says that if you’re drying corn from 28% to 15%, you’re doing about twice as much work as if you were drying 22% moisture corn down to 15%.”

Enhanced drying efficiency.

Commercial tower dryers regulate temperature and unloading rate, ensuring consistent drying regardless of conditions. Brock Commercial Tower Dryers utilize advanced technologies such as pressure heat and vacuum cooling that reclaims heat energy through the lower portion of the grain column to maximize drying efficiency.

Efficient utilization of space.

Knobloch also points out that space utilization is an important consideration for many farm grain systems. “You can get a lot of drying capacity within a minimal footprint with a commercial tower dryer. All you need is an 18-foot or 24-foot circle and then you can build up to get the drying capacity you need. To get that same capacity in a mixed flow dryer, you would need a 50-foot long by 10-foot-wide space.”

Moisture-based dryer control.

INTUI-DRY® Dryer Control comes standard on BROCK® Commercial Tower Dryers. It works in concert with the TrueGrain™ Moisture Sensor System to provide accurate and consistent moisture-based dryer control and remote monitoring.

Operational flexibility.

“When the wet bin is full, the harvest stops,” said Knobloch. “It’s important to keep expensive harvest equipment operating when the weather is good. You never know when the next storm is coming. So, you don’t want dryer capacity bogging you down. Plus, the question in the back of everyone’s mind is, what is phantom yield loss costing me because I’m not out there harvesting that corn and capturing that yield.”

Commercial tower dryers provide farmers with unparalleled operational flexibility and reliability. By taking control of the drying cycle, farmers can reduce crop spoilage, enhance product quality, and capitalize on optimal market timing. The net result is improved operational efficiency and cost savings over the long term.

See the 10 ways commercial tower dryers dry grain better.

Farm consolidation and increasing yields lead to larger grain drying and conditioning systems.

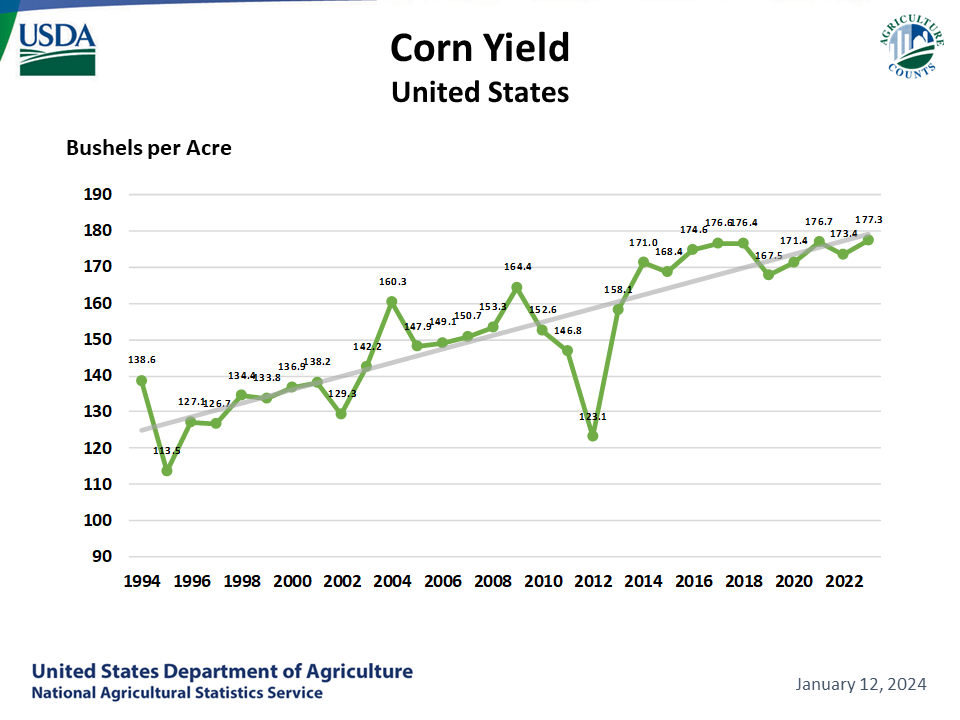

Corn yield statistics from the USDA show that, while total bushels can be up or down in a single year, the trend line continues to increase.

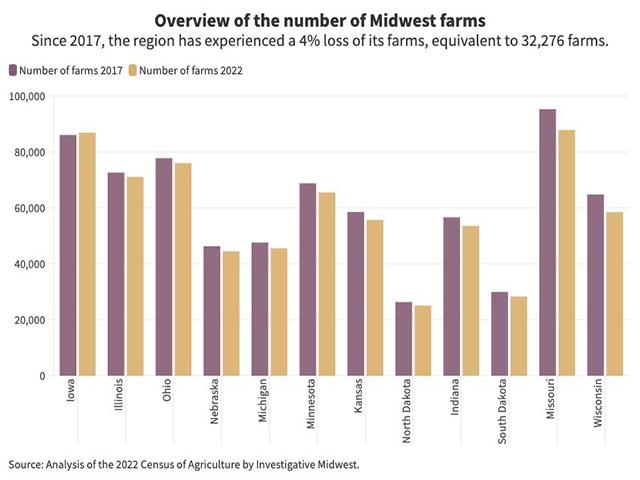

Data from the 2022 Ag Census shows that fewer, larger farms are operating on less farmland than in 2017. Nationwide, the average farm size increased by 5% in that time period.