Farmers and commercial grain system operators have two options for supporting bucket elevators and other handling equipment. They can choose diagonal guy cables that anchor to the ground in multiple locations, or they can choose a solid tower structure mounted on a single concrete foundation. Jason Hoffman, Product Manager of Structures for Brock Grain Systems reviews the pros and cons of these two support systems.

Farmers and commercial grain system operators have two options for supporting bucket elevators and other handling equipment. They can choose diagonal guy cables that anchor to the ground in multiple locations, or they can choose a solid tower structure mounted on a single concrete foundation. Jason Hoffman, Product Manager of Structures for Brock Grain Systems reviews the pros and cons of these two support systems.

Leg towers can support bucket elevators of all sizes. They are engineered for various heights, wind speeds and other environment factors. Towers can be designed for future expansion to support additional elevators, as well as distributors, conveyors and catwalk supports. Be sure to discuss potential expansion needs with your Brock dealer.

Guy cables are an acceptable option to support some grain bucket elevators. Guy cables use diagonal tension to support bucket elevators up to 150 feet tall. While guy cable supports can have a lower initial installation cost than leg towers, and can be used effectively with shorter bucket elevators, there are several tradeoffs that operators need to recognize.

Site requirements

Guy Cables

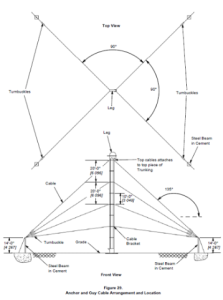

Multiple anchor locations make it difficult to work around drive lanes and other equipment. A 100-foot structure requires four anchors installed approximately 100 feet away from all sides of the elevator.

Guy cables installed correctly require a concrete footing at each anchor location as well as under the bucket elevator.

Leg Towers

A tower can be designed around spouting and other equipment with different types of access bracing.

The smaller footprint is easier to work around.

A concrete foundation is only required under the tower.

Future expansion

Guy Cables

The need for multiple guy cable anchors, limits the placement of equipment on your site.

Guyed legs will not support any type of conveyors or augers. A single bucket elevator is limited to the use of small spouts.

Leg Towers

Tower supports provide endless configuration options and make your site more versatile.

Multiple bucket elevators, horizontal drag conveyors, catwalks and distributors with multiple spouts can be accommodated by a tower structure.

Maintenance and risk to equipment

Guy Cables

Too little or too much tension in the guy cables can create twisting, bending or a complete collapse of the bucket elevator.

Changes in cable tension may cause the leg to go out of plumb, resulting in the belt not running straight.

A guyed system is not designed for high winds.

Guy cables can fray, rust or stretch causing the bucket elevator to not be properly tensioned.

Cable maintenance is suggested every 3 months. Sets of four cables are typically installed at 20-foot intervals of vertical height. That means a 100-foot structure would have 20 cables and 20 tensioners that need adjusting.

Leg Towers

Towers provide solid support that keeps bucket elevators straight and plumb.

Towers reduce the risk of movement and bending of equipment.

Towers provide rigid support that withstands high winds.

No maintenance is required on a galvanized structural tower.

Safety considerations

Guy Cables

Cables mounted at ground level can be difficult to see at dusk or dawn. Injuries can be severe or fatal if a collision happens with an ATV, tractor or other vehicle.

Brock recommends that cables be anchored to 14-foot-tall steel beams mounted in concrete to allow vehicles to pass under the cables.

Bucket Elevators with guy brackets typically use ladder, safety cage and rest platforms. Ladders can make carrying tools or parts to the top of the bucket elevator difficult.

Leg Towers

Towers provide multiple options of egress with access points at elevations within OSHA guidelines.

Options include ladder and safety cage with rest platforms, rugged switchback or wrap-around stair systems, or a combination of access configurations to create a streamlined way to access and maintain the equipment.